Our public E-LASS/RAMSSES event ended on Wednesday June 27th. The event which was held in Pornichet, France, included industry tours to STX France and iRT Jules Verne and was visited by more than 70 people with a common interest in lightweight materials and solutions.

Day 1 – Seminar day

The seminar day started off in a sunny Pornichet with a short introduction by Tommy Hertzberg, RISE. He was followed by the first speaker of the day – Thilo Bein, Fraunhofer LBF, who presented the composites research at Fraunhofer and also demonstrated several examples of their work, including a hull solution.

Next speaker was Attila Uderszky, ATEKNEA Solutions Europe, who gave a general insight of the Fibreship project. A point was made of the learning possibilities and knowledge transfer from the aviation industry to the maritime industry, something also mentioned by Thilo Bein during his presentation earlier. Worth noting is the collaboration between Fibreship and the RAMSSES project, something which Frank Roland, CMT, proposed should be developed even further in order to aid the common goal of applying lightweight solutions to the maritime sector.

David Thull, FISCO GMbH, presented their FISCO FI:resist, a non-flammable composite used for applications such as partition walls, fire roller doors, ship balconies and fire-resistant cable duct. After Thull’s presentation, Hans Hoydonckx from our sponsor TransFurans Chemicals gave an interesting insight of how they use sugar canes as a raw material before turning it into a chemical product. Transfurans use PFA thermosets in composite applications mainly used within the RAIL industry and as Hoydonckx put it:

“In a train, you can use these composites everywhere.”

After the coffee break, Bert Delbaere, DP Survey Group, shared an interesting presentation on the topic of “Lightweight materials from a surveyor point of view”. He discussed the possibility of controlling risk involved with the implementation of lightweight materials in the maritime industry. Delbaere urged the audience to consider damage and repair a design criterion and not something to think of afterwards, as the costs for maintenance and repair is often very high.

Next was Peter Norlin, DIAB. He gave a very pedagogical insight of how to understand sandwich composites and also shared a couple of historical anecdotes. What makes composites such an interesting material he concluded with one sentence:

“With composites material and sandwiches, you can engineer something with the components you want to have and hopefully the cost has not increased by too much.”

Unfortunately, two presentations were canceled at the last minute as the speakers could not attend the event. This meant the seminar instead continued after lunch with a presentation about E-Ferry by Trine Heinemann, Ærø Municipality. It is an EU project aiming to develop battery driven vessels meant cover large distances and was initiated in 2015.

Next up was Jürgen Reichert (Roma Strickstoffe) and Werner Moser (Eschler Textile GmbH), together representing the German association of textile producers called AFBW. They produce specialized textiles used mainly for automotive applications. One example of this was the “spacer textiles” often used within the sports industry, a small sample was handed out to the participants to show that it can also be a product for other usage areas. According to the speakers, panel heating can be integrated, or a computer can be put behind the textile wall where you still see through it, I.E there are many application areas for this sort of product.

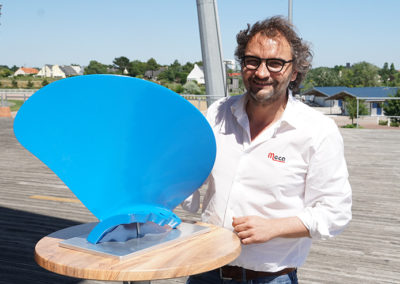

Then there was the presentation of a composite propeller by Samuel Durand and Pol Muller, Méca. They shared in detail how they developed the propeller with the first concept being developed back in 2016. They also brought a 6-kilo prototype which everyone could have a look at. Melanie Diziol, InSensus Project, then presented the award-winning Smart Skin sensor system. The sensor measures four main values – strain, temperature, tilt and seismic activity and this data is then sent to a cloud database. The sensor system has a clear advantage of not having to be integrated but instead is an easy installation with a life span based on the battery size which makes it possible to adapt the product to its usage area, or if you put it like Ms. Diziol:

“Just stick it under a bridge and it will stay there for 20 years, just like the bridge will.”

Our last speaker of the day was Susanne Schwarzwälder from our sponsor Matmatch. She presented their search engine which is supposed to be a digital platform for material selection. The idea is to help users in the selection process in order to get an overview of the potential materials and then being able to contact the suppliers directly through Matmatch. The search engine is currently free of charge for users and is expected to remain like that:

“We are looking to democratize materials as most of the information is already available, it’s just not that easy to search for or to compare.”

Our seminar day was concluded by a short introduction of the two RAMSSES partners hosting the industry tours – the research institute iRT Jules Verne and the shipyard STX France.

Day 2 – Industry Tour

The second day of our public E-LASS/RAMSSES event started off at the meeting point of Place du 8 MAI, Pornichet. The participants were divided into two groups, one heading to STX Shipyard and the other one going to iRT Jules Verne. At STX Shipyard, the participants got to ride around in the yard for a short bus tour before walking around divided in 4 groups with one STX employee acting as guide for each group. Among the most impressive things was STX’s dry dock – the largest one in Europe. Walking around in the shipyard made most of us feel like ants as everything there is plus size. For example, one of their cranes can lift up to 1400 tons, which says a lot about the size of the ships being built.

The highlight of the STX industry tour was the visit to cruise ship MSC Bellisima, which is currently being constructed. Having the unique opportunity to walk around in this massive vessel was very appreciated by everyone there. The vessel which is expected to be finished in 2019 is the second out of four ships built for MSC.

Simply watching the way STX assemble the cruise ships was very interesting and as our guide put it:

“It’s like building with Lego actually, but very high level.” – true words of an engineer.

Thanks to everyone participating in this event and also a big thanks to our hosts STX France and iRT Jules Verne, and of course our sponsors Matmatch, TransFurans Chemicals, RISE, and the RAMSSES project for making this event possible. See you all in Piteå January 2019!

All presentations can be found below:

Research:

Fraunhofer LBF – Thilo Bein

Fibreship – Attila Uderszky

iRT Jules Verne – Julio Cesar de Luca

E-FERRY – Trine Heinemann

Materials:

FISCO – David Thull

Transfurans Chemicals – Hans Hoydonckx

DP Survey Group – Bert Delbaere

DIAB – Peter Norlin

Application & Processes:

AFBW – Jürgen Reichert & Werner Moser

Méca – Samuel Durand & Pol Muller

InSensus Project – Melanie Diziol

Matmatch – Susanne Schwarzwälder