Luxembourg/Thimister, 27 February 2020 – Armacell, a global leader in flexible foam for the equipment insulation market and a leading provider of engineered foams, today announced the partnership with Swiss CMT, an engineering company with significant expertise in composite materials and technologies, to join forces in the development and industrialisation of ArmaShape, the first particle foam made from 100 percent recycled PET.

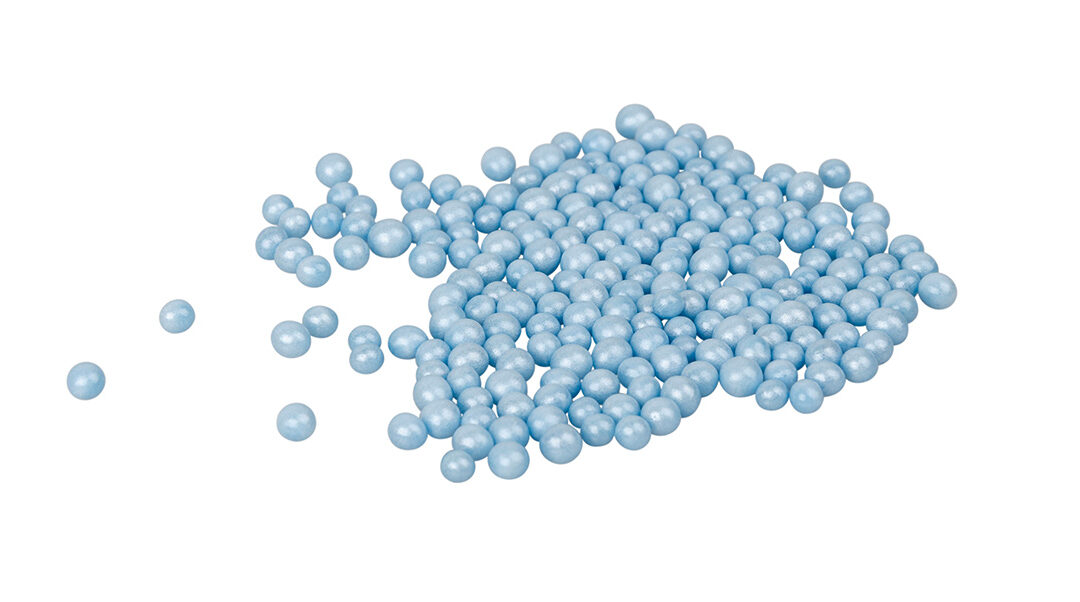

In this joint venture, the two companies focus on pre-coating ArmaShape loose beads with a hybrid resin system. The new approach of applying a thermally curable coating enhances the moulding process and provides permanent bonding and good adhesion to multiple materials, e.g. glass or carbon fibres and metal or plastic inserts.

“The core competency of Armacell is the extrusion of expandable PET with properties tailored for various industrial applications,” explained Dr Justyna Dolega, Global Innovation Manager at Armacell. “The development partnership with Swiss CMT provides us with additional product capabilities, providing easier and faster moulding into three-dimensional parts. Going forward, we can even better meet the expectations of our customers to create complex shapes for several application areas in the automotive, sports and leisure, and transport industries,” Dolega added. “This is our solution for cost-effective serial production of structural composite parts with the highest level of design flexibility and sustainable responsibility,“ said Bart Janssen, Armacell’s Vice President of Engineered Foams.

Marcel Schubiger, General Manager at CMT, commented:

“The new thermally curable and pre-coated ArmaShape solution allows for new multi-material combinations and paves the way to the next level of innovative lightweight design.”

Armacell’s latest PET foam innovation is designed to create complex, waste-free and ready-to-use 3D shaped foam cores for composite sandwich structures. It brings significant benefits to many industries where lightweight yet strong plastic parts are prerequisites for a successful product design. ArmaShape combines superior mechanical properties of structural foam cores with the advantages of particle foams. Made from 100 percent recycled PET, ArmaShape can be recycled again after its use phase, representing a highly sustainable alternative to comparable materials.